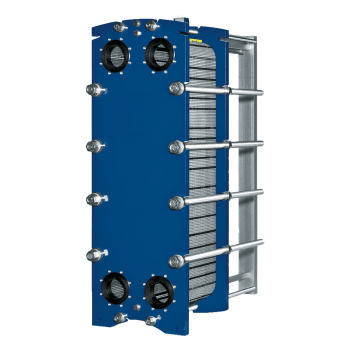

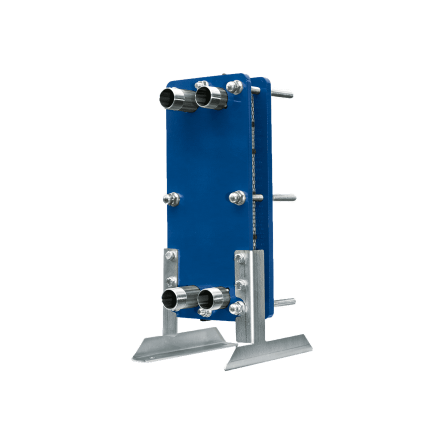

Gasketed plate heat exchangers

GASKETED PLATE ITEX

ITEX gasketed plate heat exchangers are particularly well suited to exchanges between two fluids, and therefore to a wide range of applications.

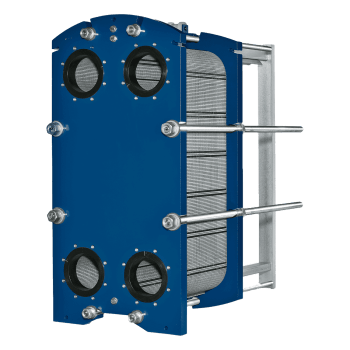

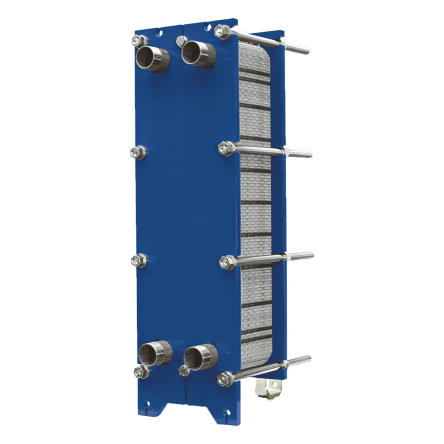

Water flow rate: up to 800 m3/h

Plate material: 304 stainless steel - 316L stainless steel - 254 SMO (except 10TEE990+) - titanium

Gasket material: NBR - EPDM Prx - FPM

Frame material: carbon steel - stainless steel

18 models available

Liquid flow rates: up to 800 m3/h

Pressure: up to 25 bar

ITEX gasketed plate heat exchangers are particularly well suited to exchanges between two fluids, and therefore to a wide range of applications:

- Heating sub-stations

- Domestic water heating

- Swimming pool heating

- Buffer on heat pump

- Recovery from corrosive discharge

- Geothermal energy

- Oil refrigeration

- Industrial processes

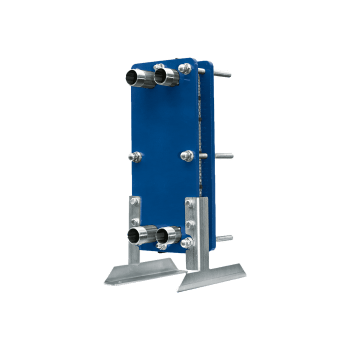

- Excellent transfer coefficient, reduced surface area

- Ultra-slim: takes up little space

- Easy to install

- Easy to maintain

- Very low pinch-point temperature possible

- High corrosion resistance

- Low-capacity circuits

- Plates can be added to meet changes in capacity demand

- Unit can be cleaned in-place using a circulation system (NEP or CIP)

- Max. differential pressure = max. operating pressure

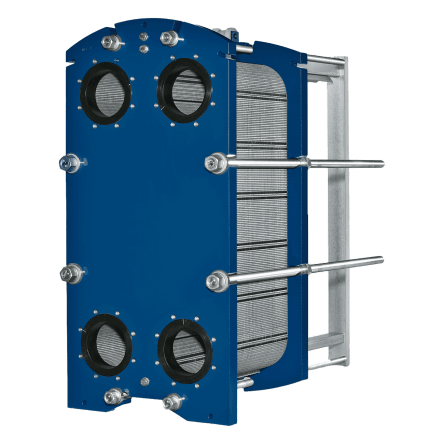

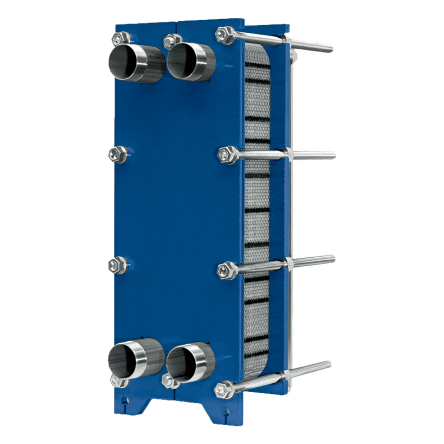

18 models available

Liquid flow rates: up to 800 m3/h

Pressure: up to 25 bar

ITEX gasketed plate heat exchangers are particularly well suited to exchanges between two fluids, and therefore to a wide range of applications:

- Heating sub-stations

- Domestic water heating

- Swimming pool heating

- Buffer on heat pump

- Recovery from corrosive discharge

- Geothermal energy

- Oil refrigeration

- Industrial processes

- Excellent transfer coefficient, reduced surface area

- Ultra-slim: takes up little space

- Easy to install

- Easy to maintain

- Very low pinch-point temperature possible

- High corrosion resistance

- Low-capacity circuits

- Plates can be added to meet changes in capacity demand

- Unit can be cleaned in-place using a circulation system (NEP or CIP)

- Max. differential pressure = max. operating pressure

Commercial brochure

Instruction manual