Heat pumps and chillers control module

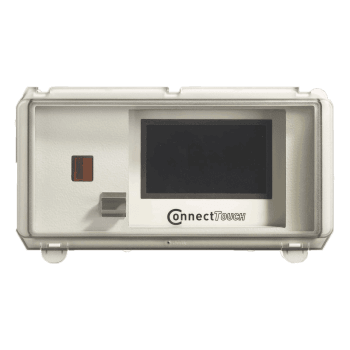

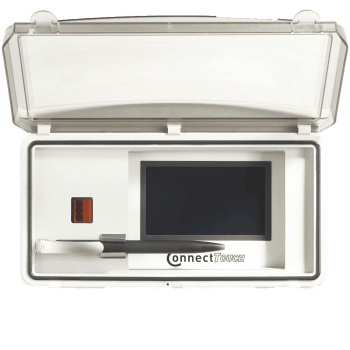

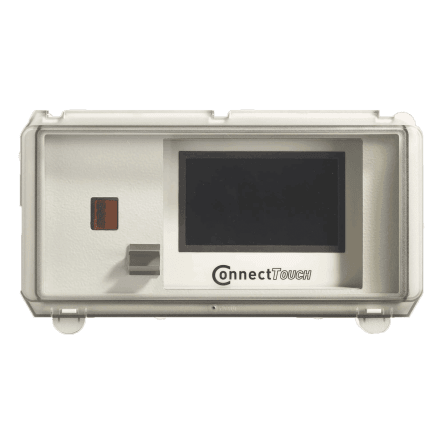

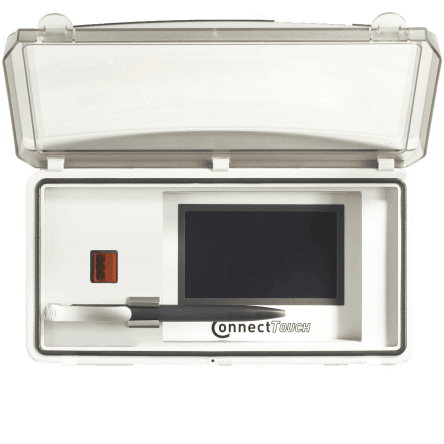

CONNECT TOUCH

Control module for water-to-water or air-to-water heat pumps or for medium-capacity reversible or cooling-only water-cooled or air-cooled chillers with scroll compressor.

4’’ 1/3 or 5’’ color touchscreen

Multilingual

Numerous configurable features

Communication GTC/GTB via ModBus-JBus protocol

One model available

Controls up to two refrigerant circuits and eight scroll compressors

Control module for water-to-water or air-to-water heat pumps or for medium-capacity reversible or cooling-only water-cooled or air-cooled chillers with scroll compressor.

- 4’’ 1/3 or 5’’ color touchscreen depending on product range

- Motherboard for a unit with scroll compressor and up to two refrigerant circuits and eight compressors

- Pressure sensor

- CPU board and software

- Multilingual (English-French-German-Dutch-Italian-Spanish-Portuguese + Chinese)

- Unit configuration

- Reading of unit states

- Monitoring of chilled-water or hot-water temperatures

- Two setpoint values

- Setpoint adjustment based on outdoor temperature

- Condensation pressure control (all-season operation on air-cooled units)

- Control of unit components (compressors, fans, pumps, etc.)

- Control of compressor stages or electrical auxiliary

- Optimization of stages to achieve best seasonal efficency SEER/SEPR/SCOP

- Compressor operating time balancing

- Control of safety devices (high and low pressure, discharge temperature, motor overload, water circulation fault, frost point, etc.), and load shedding

- Operating status and fault LEDs, fault history

- Web server

- ModBus-JBus protocol as standard

- LonWorks and BacNet protocol optional

- Intuitive navigation using icons

- Direct access to the word sequence and value for each parameter

- 3 password-protected access levels (user, maintenance, factory)

- User-friendly, trouble-free operation, easy-to-read screen

- Two programmable setpoints

- Wide range of control types

- Diagnostic support, fault storage system and black box

- Large range of auto adaptive functions

- Continuous monitoring of operating settings

- Trending curves

- Balancing of compressor and pump operating times

- Self-adjusting control of safety components and frost-protection components

- Many remote-control options

- Two programable schedule (on/off set-point 1 or 2)

- Maintenance programable schedule

- Leak detection programable schedule (according F-gas regulation)

- Communication interfaces, RS-485 output, open BMS communications protocol (standard-LON ModBus optional)

One model available

Controls up to two refrigerant circuits and eight scroll compressors

Control module for water-to-water or air-to-water heat pumps or for medium-capacity reversible or cooling-only water-cooled or air-cooled chillers with scroll compressor.

- 4’’ 1/3 or 5’’ color touchscreen depending on product range

- Motherboard for a unit with scroll compressor and up to two refrigerant circuits and eight compressors

- Pressure sensor

- CPU board and software

- Multilingual (English-French-German-Dutch-Italian-Spanish-Portuguese + Chinese)

- Unit configuration

- Reading of unit states

- Monitoring of chilled-water or hot-water temperatures

- Two setpoint values

- Setpoint adjustment based on outdoor temperature

- Condensation pressure control (all-season operation on air-cooled units)

- Control of unit components (compressors, fans, pumps, etc.)

- Control of compressor stages or electrical auxiliary

- Optimization of stages to achieve best seasonal efficency SEER/SEPR/SCOP

- Compressor operating time balancing

- Control of safety devices (high and low pressure, discharge temperature, motor overload, water circulation fault, frost point, etc.), and load shedding

- Operating status and fault LEDs, fault history

- Web server

- ModBus-JBus protocol as standard

- LonWorks and BacNet protocol optional

- Intuitive navigation using icons

- Direct access to the word sequence and value for each parameter

- 3 password-protected access levels (user, maintenance, factory)

- User-friendly, trouble-free operation, easy-to-read screen

- Two programmable setpoints

- Wide range of control types

- Diagnostic support, fault storage system and black box

- Large range of auto adaptive functions

- Continuous monitoring of operating settings

- Trending curves

- Balancing of compressor and pump operating times

- Self-adjusting control of safety components and frost-protection components

- Many remote-control options

- Two programable schedule (on/off set-point 1 or 2)

- Maintenance programable schedule

- Leak detection programable schedule (according F-gas regulation)

- Communication interfaces, RS-485 output, open BMS communications protocol (standard-LON ModBus optional)