Heat pumps and chillers control module

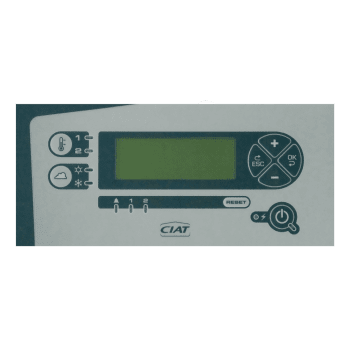

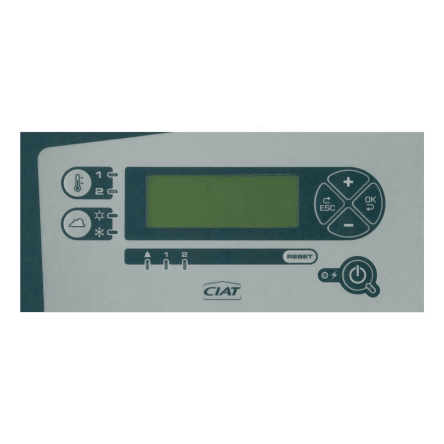

CONNECT2

Control module for water-to-water or air-to-water heat pumps or for medium-capacity reversible or cooling-only water-cooled or air-cooled chillers with scroll compressor.

Multilingual

Numerous configurable features

Communication GTC/GTB via ModBus-JBus protocol

One model available

Controls up to two refrigerant circuits and six scroll compressors

Control module for water-to-water or air-to-water heat pumps or for medium-capacity reversible or cooling-only water-cooled or air-cooled chillers with scroll compressor.

Motherboard for a unit with scroll compressor and up to two refrigerant circuits and six compressors

- Backlit LCD, status LEDs

- Pressure sensor

- CPU board and CIAT-defined software

- Ergonomic keypad

- Multilingual

- Unit configuration

- Reading of unit states

- Monitoring of chilled-water or hot-water temperatures

- Two setpoint values

- Setpoint adjustment based on outdoor temperature

- Condensation pressure control (all-season operation on air-cooled units)

- Control of unit components (compressors, fans, pumps, etc.)

- Control of compressor stages or electrical auxiliary

- Optimization of stages to achieve best ESEER

- Compressor operating time balancing

- Control of safety devices (high and low pressure, discharge temperature, motor overload, water circulation fault, frost point, etc.), and load shedding

- Operating status and fault LEDs, fault history

- ModBus-JBus protocol on RS-485 & ethernet as standard

- LonWorks and BacNet (IP or MSTP) protocol optional

- Backlit LCD

- User-friendly, trouble-free operation, easy-to-read screen

- Two programmable setpoints

- Four control options

- Troubleshooting

- Many self-regulating functions

- Optimized defrost DEGIPAC system

- Continuous monitoring of operating settings

- Balancing of compressor and pump operating times

- Self-adjusting control of safety components and frost-protection components

- Many remote-control options

- Communication interfaces, RS-485 output, open BMS communications protocol (standard-LON ModBus optional)

One model available

Controls up to two refrigerant circuits and six scroll compressors

Control module for water-to-water or air-to-water heat pumps or for medium-capacity reversible or cooling-only water-cooled or air-cooled chillers with scroll compressor.

Motherboard for a unit with scroll compressor and up to two refrigerant circuits and six compressors

- Backlit LCD, status LEDs

- Pressure sensor

- CPU board and CIAT-defined software

- Ergonomic keypad

- Multilingual

- Unit configuration

- Reading of unit states

- Monitoring of chilled-water or hot-water temperatures

- Two setpoint values

- Setpoint adjustment based on outdoor temperature

- Condensation pressure control (all-season operation on air-cooled units)

- Control of unit components (compressors, fans, pumps, etc.)

- Control of compressor stages or electrical auxiliary

- Optimization of stages to achieve best ESEER

- Compressor operating time balancing

- Control of safety devices (high and low pressure, discharge temperature, motor overload, water circulation fault, frost point, etc.), and load shedding

- Operating status and fault LEDs, fault history

- ModBus-JBus protocol on RS-485 & ethernet as standard

- LonWorks and BacNet (IP or MSTP) protocol optional

- Backlit LCD

- User-friendly, trouble-free operation, easy-to-read screen

- Two programmable setpoints

- Four control options

- Troubleshooting

- Many self-regulating functions

- Optimized defrost DEGIPAC system

- Continuous monitoring of operating settings

- Balancing of compressor and pump operating times

- Self-adjusting control of safety components and frost-protection components

- Many remote-control options

- Communication interfaces, RS-485 output, open BMS communications protocol (standard-LON ModBus optional)