Control and supervision of air-to-air units

VECTIC

The Vectic control is an electronic module with microprocessor designed for the control and supervision of air-air units (especially rooftop models). This control is implemented in the all CIAT rooftops: VECTIOS and VECTIOSPOWER.

Different terminal options (user / maintenance)

Multilingual

Numerous configurable features

BMS communication

This control enables unit integration with local supervision solutions: pCO Web (1 unit); BOSS mini (up to 50 units) and BOSS (up to 300 units), as well as with the remote solution.

Management of units up to 2 frigorific circuits and 4 scroll compressors with electronic expansion valves, indoor EC plug-fans, outdoor axial fans (EC or AC 2 speed), energy recovery and many other options.

The Vectic control is an electronic module with microprocessor designed for the control and supervision of air-air units (especially rooftop models).

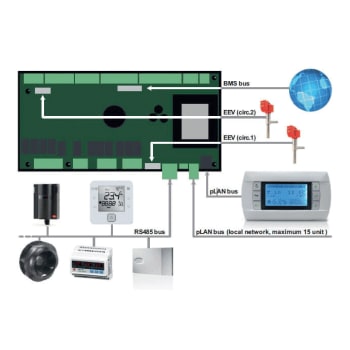

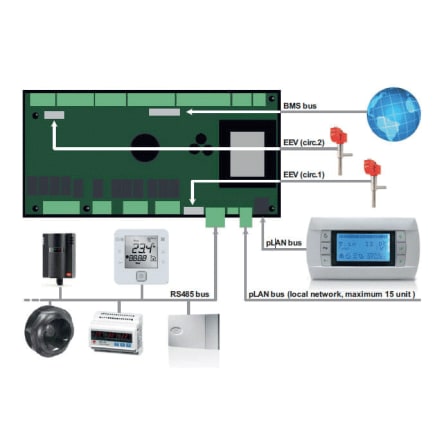

This control consist of a control board, sensors, a VecticGD graphic terminal, and a TCO user terminal (optional).

This system uses a RS485 field-bus to manage additional components such as: pCOe expansion modules, SMALL board, plug-fans, probes of temperature or relative humidity of the ambient air, leak detectors, energy meters, etc.

A BMS card (optional) allows the control board to be connected to a centralised technical management system with the following communication protocols: Carel, Modbus, LonWorks®, BACnetTM MSTP, Konnex, Modbus TCP/IP, BACnetTM Ethernet, TCP/IP, SNMP V1-2-3, FTP and HTTP.

It also manages a local connection between units through a pLAN network (μPC MEDIUM Local Area Network), allowing data and information to be exchanged between units, for a maximum of 15 units. This enables the reduction of the number of graphic terminals, since a single shared terminal can monitor all boards in the network.

Main functions:

- Selection of operating mode: HEATING / COOLING / AUTO / VENTILATION

- Selection of setpoint

- Continuous control of the operating parameters

- Display of the values measured by the sensors

- Compressors time delays

- Defrosting management (heat pump units)

- Control of the supply air temperature

- All-seasons operation via the condensation and evaporation pressure control

- Setpoint compensation based on the outdoor temperature

- Hourly and weekly schedule (possibility of 3 setpoints)

- Fire protection

- Diagnosis of faults and general alarm

Optional functions:

This control is used to manage addition components such as:

- External air damper for the renewal of fresh air, depending on the temperature of the mixed air or depending on the air quality sensor

- Mixing box for thermal, enthalpy or thermo-enthalpy free-cooling

- Rotary heat exchanger. Wheel speed with on/off control or variable control

- Cooling circuit for the recovery of the extracted air energy

- Control of the overpressure

- Zoning of the air fl ow up to 4 different areas

- Low return temperature application

- Auxiliary electrical heaters: two-stage with on/off control or singlestage with proportional control

- Hot water coil with 3-way valve, with proportional or on/off control

- Gas burner with proportional control

- Gas boiler with proportional control

- Heat recovery coil with 3-way valve, with proportional control

- Humidifier with proportional or on/off control

- Clogged filter pressostat

- Smoke detection station

- Refrigerant leak detector

- Air quality sensor for measuring CO2

- Energy meter and calculation of the cooling and heating capacities

- Backlit LCD screen : VecticGD graphic terminal

- Simple and easy to use, communication display

- Troubleshooting

- Continuous monitoring of operating parameters

- Balancing of compressor and pump running times

- Management of electronic expansion valves

- Programmable hourly and weekly time schedules (six separate daily time periods with the possibility of different setpoints and/or switching the unit on/off)

- Many digital and analogue inputs and outputs

- TCO user terminal en option instead of VecticGD graphic terminal (without access to parameters)

- Up to 4 ambient sensors

- Remote control possible

- Management of indoor air quality via CO2 sensor

- Management of NEW interesting options:

- Management up to 4 different zones (variable air flow)

- Low return temperatura application

- Heat recovery coil

- Signal control for external humidifier

- Supplementary condenser coil for dehumidification

- Mountings 100% fresh air

- Integration in a PLAN network (up to 15 units)

- Communication interfaces: Modbus or Carel RS-485 output, open BMS communication protocol for (LonWorks,BACnet, Konnex and Ethernet)

- BOSS and BOSS mini supervision system as an option

Management of units up to 2 frigorific circuits and 4 scroll compressors with electronic expansion valves, indoor EC plug-fans, outdoor axial fans (EC or AC 2 speed), energy recovery and many other options.

The Vectic control is an electronic module with microprocessor designed for the control and supervision of air-air units (especially rooftop models).

This control consist of a control board, sensors, a VecticGD graphic terminal, and a TCO user terminal (optional).

This system uses a RS485 field-bus to manage additional components such as: pCOe expansion modules, SMALL board, plug-fans, probes of temperature or relative humidity of the ambient air, leak detectors, energy meters, etc.

A BMS card (optional) allows the control board to be connected to a centralised technical management system with the following communication protocols: Carel, Modbus, LonWorks®, BACnetTM MSTP, Konnex, Modbus TCP/IP, BACnetTM Ethernet, TCP/IP, SNMP V1-2-3, FTP and HTTP.

It also manages a local connection between units through a pLAN network (μPC MEDIUM Local Area Network), allowing data and information to be exchanged between units, for a maximum of 15 units. This enables the reduction of the number of graphic terminals, since a single shared terminal can monitor all boards in the network.

Main functions:

- Selection of operating mode: HEATING / COOLING / AUTO / VENTILATION

- Selection of setpoint

- Continuous control of the operating parameters

- Display of the values measured by the sensors

- Compressors time delays

- Defrosting management (heat pump units)

- Control of the supply air temperature

- All-seasons operation via the condensation and evaporation pressure control

- Setpoint compensation based on the outdoor temperature

- Hourly and weekly schedule (possibility of 3 setpoints)

- Fire protection

- Diagnosis of faults and general alarm

Optional functions:

This control is used to manage addition components such as:

- External air damper for the renewal of fresh air, depending on the temperature of the mixed air or depending on the air quality sensor

- Mixing box for thermal, enthalpy or thermo-enthalpy free-cooling

- Rotary heat exchanger. Wheel speed with on/off control or variable control

- Cooling circuit for the recovery of the extracted air energy

- Control of the overpressure

- Zoning of the air fl ow up to 4 different areas

- Low return temperature application

- Auxiliary electrical heaters: two-stage with on/off control or singlestage with proportional control

- Hot water coil with 3-way valve, with proportional or on/off control

- Gas burner with proportional control

- Gas boiler with proportional control

- Heat recovery coil with 3-way valve, with proportional control

- Humidifier with proportional or on/off control

- Clogged filter pressostat

- Smoke detection station

- Refrigerant leak detector

- Air quality sensor for measuring CO2

- Energy meter and calculation of the cooling and heating capacities

- Backlit LCD screen : VecticGD graphic terminal

- Simple and easy to use, communication display

- Troubleshooting

- Continuous monitoring of operating parameters

- Balancing of compressor and pump running times

- Management of electronic expansion valves

- Programmable hourly and weekly time schedules (six separate daily time periods with the possibility of different setpoints and/or switching the unit on/off)

- Many digital and analogue inputs and outputs

- TCO user terminal en option instead of VecticGD graphic terminal (without access to parameters)

- Up to 4 ambient sensors

- Remote control possible

- Management of indoor air quality via CO2 sensor

- Management of NEW interesting options:

- Management up to 4 different zones (variable air flow)

- Low return temperatura application

- Heat recovery coil

- Signal control for external humidifier

- Supplementary condenser coil for dehumidification

- Mountings 100% fresh air

- Integration in a PLAN network (up to 15 units)

- Communication interfaces: Modbus or Carel RS-485 output, open BMS communication protocol for (LonWorks,BACnet, Konnex and Ethernet)

- BOSS and BOSS mini supervision system as an option