Control module for dry coolers and air-cooled condensers

AEROCONNECT 1B

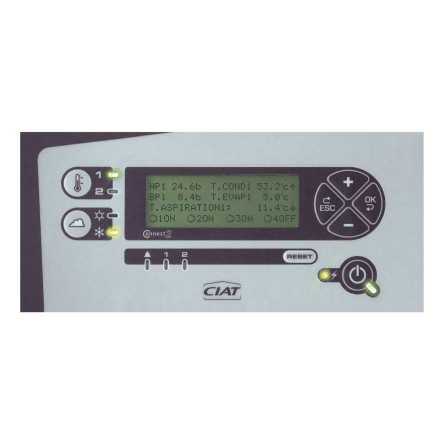

AeroCONNECT 1B is a control module for dry coolers and air-cooled condensers.

One model available

Control module for dry coolers and air-cooled condensers

- Main board

- Backlit LCD, status LEDs

- Pressure sensor and/or temperature sensor depending on the application

- CPU board and CIAT-defined software

- Ergonomic keypad

- Multilingual

- Unit configuration

- Reading of unit states

- Monitoring of chilled-water or hot-water temperatures

- Two setpoint values

- Control

- Control of the unit's devices (fans, associated free-cooling valves etc.)

- Control of the AEROFRESH ™ misting function

- Control of compressor stages or electrical auxiliary

- Optimisation of the stages for improved efficiency

- Control of safety devices

- Operating status and fault LEDs, fault history

- Communication with CONNECT2 and XTRACONNECT2 controllers fitted to CIAT heat pumps and chillers

- Optimisation of Aero and heat pump/chiller system operation

- ModBus-JBus protocol on RS-485 & ethernet as standard

- LonWorks and BacNet (IP or MSTP) protocol optional

- Backlit LCD

- User-friendly, trouble-free operation, easy-to-read screen

- Two programmable setpoints

- Troubleshooting

- Many self-regulating functions

- Continuous monitoring of operating settings

- Balancing operating times

- Self-adjusting control of safety components

- Many remote-control options

- Communication interfaces, RS-485 output, open BMS communications protocol (standard- ModBus and BacNet optional)

One model available

Control module for dry coolers and air-cooled condensers

- Main board

- Backlit LCD, status LEDs

- Pressure sensor and/or temperature sensor depending on the application

- CPU board and CIAT-defined software

- Ergonomic keypad

- Multilingual

- Unit configuration

- Reading of unit states

- Monitoring of chilled-water or hot-water temperatures

- Two setpoint values

- Control

- Control of the unit's devices (fans, associated free-cooling valves etc.)

- Control of the AEROFRESH ™ misting function

- Control of compressor stages or electrical auxiliary

- Optimisation of the stages for improved efficiency

- Control of safety devices

- Operating status and fault LEDs, fault history

- Communication with CONNECT2 and XTRACONNECT2 controllers fitted to CIAT heat pumps and chillers

- Optimisation of Aero and heat pump/chiller system operation

- ModBus-JBus protocol on RS-485 & ethernet as standard

- LonWorks and BacNet (IP or MSTP) protocol optional

- Backlit LCD

- User-friendly, trouble-free operation, easy-to-read screen

- Two programmable setpoints

- Troubleshooting

- Many self-regulating functions

- Continuous monitoring of operating settings

- Balancing operating times

- Self-adjusting control of safety components

- Many remote-control options

- Communication interfaces, RS-485 output, open BMS communications protocol (standard- ModBus and BacNet optional)

Documents

Commercial brochure

Controls manual

Kit / option manual